introduction to products:

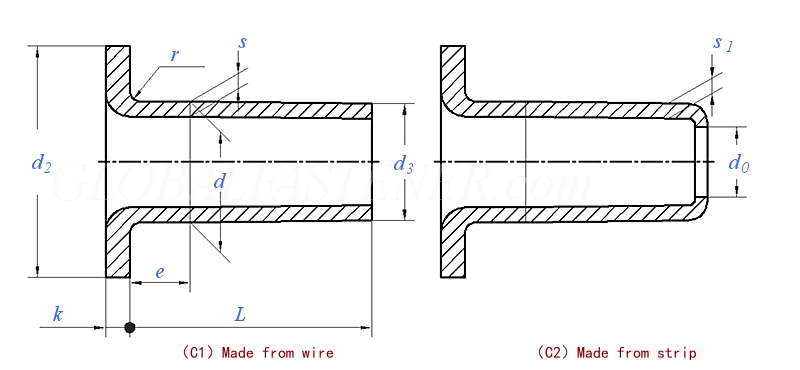

Galvanized Zinc Plated DIN7340 Knurled Blind Rivet Nuts are cylindrical fasteners with knurled outer walls and internal threads. The knurling enhances grip on thin workpieces (like sheet metal, square tubes), while galvanized zinc plating resists rust. Made from carbon steel (cost - effective for general use) or stainless steel (corrosion - proof for damp environments), they enable blind riveting — no back - side access required. Following the DIN7340 standard, they come in metric sizes (M3–M12) and are used to add internal threads to thin materials in automotive (license plate mounts), furniture (metal frame assembly), and construction (light - duty structural connections).

Instructions for Use:

To install, drill a hole in the workpiece matching the nut’s diameter. Insert the rivet nut into the hole, then use a rivet tool (manual/electric) to pull it, making the knurled wall embed into the material. Ensure the tool matches the nut size (e.g., an M6 nut needs an M6 - compatible tool). Regularly check the galvanized coating for scratches (repair with anti - rust paint) and the knurling for wear (replace if slipping occurs).

| Nominal Diameter | 3 | 4 | 5 | 6 | 8 | 10 | |

| d | |||||||

| d | max=nominal size (h13) | 3 | 4 | 5 | 6 | 8 | 10 |

| min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | |

| d2 | max=nominal size | 5.5 | 7.5 | 9.5 | 11.5 | 15.5 | 18 |

| min | 5.2 | 6.92 | 8.92 | 10.8 | 14.8 | 17.3 | |

| d3 | min | 2.85 | 3.8 | 4.8 | 5.8 | 7.75 | 9.75 |

| d0 | max=nominal size | 1.66 | 2.62 | 3.42 | 4.12 | 5.18 | 7.18 |

| min | 1.26 | 2.22 | 3.02 | 3.72 | 4.78 | 6.78 | |

| e | max | 1.5 | 2 | 2.5 | 3 | 4 | 5 |

| k | max | 0.8 | 1 | 1 | 1.2 | 1.2 | 1.4 |

| min | 0.6 | 0.8 | 0.8 | 1 | 1 | 1.2 | |

| r | max | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.6 |

| s | Nominal Size | 0.5 | 0.5 | 0.6 | 0.75 | 1.2 | 1.2 |

| max | 0.6 | 0.6 | 0.7 | 0.85 | 1.3 | 1.3 | |

| min | 0.4 | 0.4 | 0.5 | 0.65 | 1.1 | 1.1 | |

| s1 | min | 0.4 | 0.4 | 0.5 | 0.6 | 1 | 1 |

| Weight of per 1000 steel products(≈kg) | - | - | - | - | - | - | |

Hebei Duojia Metal Products Co., Ltd. was formerly known as Yonghong Expansion Screw Factory. It has over 25 years of professional experience in manufacturing fasteners. The factory is located in the China Standard Room Industrial Base - Yongnan District, Handan City. It conducts online and offline production and manufacturing of fasteners as well as one-stop sales service business.

The factory covers an area of over 5,000 square meters, and the warehouse covers an area of over 2,000 square meters. In 2022, the company carried out industrial upgrading, standardized the production order of the factory, improved the storage capacity, enhanced safety production capacity, and implemented environmental protection measures. The factory has achieved a preliminary green and environmentally friendly production environment.

The company has cold pressing machines, stamping machines, tapping machines, threading machines, forming machines, spring machines, crimping machines, and welding robots. Its main products are a series of expansion screws known as "wall climbers".

It also produces special-shaped hook products such as wood tooth welding sheep eye ring screws and machine tooth sheep eye ring bolts. In addition, the company has expanded new product types from the end of 2024. It focuses on pre-buried products for the construction industry.

The company has a professional sales team and a professional follow-up team to safeguard your products. The company guarantees the quality of the products it offers and can conduct inspections on the grades. If there are any problems, the company can provide professional after-sales service.

Our export countries include Russia, South Korea, Britain, France, Germany, Italy, Canada, Mexico,Brazil, Argentina, Chile, Australia, Indonesia, Thailand, Singapore, Saudi Arabia, Syria, Egypt, Tanzania.Kenya and other countries. Our products will be spread all over the world!

WHY CHOOSE US?

1.As a factory-direct upplier,we eliminate middleman margis to offer you the most competitive pricing for high-quality fasteners.

2.our factory pass the ISO 9001 and AAA certification .we have the hardness testing and the test of zinc coating thickness for galvanized products.

3.with full contrl over production and logistic,we guarantee on-time delivery even for urgnt orders .

4.our engineering team can customize faseners from prototype to mass production , including unique thread designs and anti-corrosion coatings.

5.From carbon steel hex bolts to high-tensile anchor bolts ,we provide a one-stop solution for all your fastener needs.

6.If any defect is found ,we’ll reship replacements within 3weeks of our cost .