Product Description

Hexagon Nuts (with Various Surface Treatments and Materials)

Instructions for Use:

- Matching Check: Select the appropriate specification (matching the bolt size) and material/surface treatment (considering factors like corrosion resistance and application environment) according to the assembly requirements.

- Pre - use Inspection: Before use, check for damage, deformation, or thread abnormalities on the nut body.

- Installation Requirement: When installing, use tools like wrenches to cooperate with matching bolts for fastening. Ensure the matching of material and surface treatment with the actual working conditions.

- Force Application: During installation, apply force evenly to avoid uneven stress that may cause nut or bolt damage. Strictly prohibit over - force that may lead to thread damage.

- Maintenance: Regularly check for rust, loosening, or thread damage in different use environments. If any defects affecting the fastening performance are found, repair or replace the nuts in a timely manner.

| Standard | GB/DIN/ISO/JIS |

| Material | carbon steel, stainless steel, brass, alloy steel |

| Finish | Normal, galvanized, black oxide, H.D.G, etc |

| Packing | boxes, cartons or plastic bags, or according to customer demand |

| Hex nuts are used in conjunction with bolts and screws to tighten fasteners. | |

| We can produce hexagonal nuts in different materials such as carbon steel and stainless steel. For product details and better price list please contact us. | |

Product details

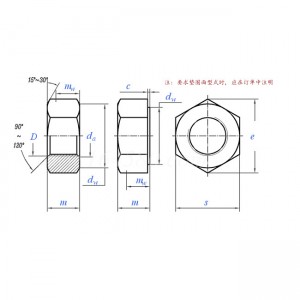

| Thread sized | M10 | M12 | M14 | M16 | M20 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | |

| P | Pitch | 2.5 | 3 | 3 | 3.5 | 3.5 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 |

| da | maximum | 10.8 | 13 | 15..1 | 17.3 | 21.6 | 25.9 | 29.1 | 32.4 | 35.6 | 38.9 | 42.1 | 45.4 | 48.6 | 51.8 | 56.2 | 60.5 |

| minimum | 10 | 12 | 14 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | 52 | 56 | |

| dw | minimum | 14.6 | 16.6 | 19.6 | 22.5 | 27.7 | 33.3 | 38 | 42.8 | 46.6 | 51.1 | 55.9 | 60 | 64.7 | 69.5 | 74.2 | 78.7 |

| e | minimum | 17.77 | 20.03 | 23.36 | 26.75 | 32.95 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 |

| m | maximum | 9.3 | 12 | 14.1 | 16.4 | 20.3 | 23.9 | 26.7 | 28.6 | 32.5 | 34.7 | 39.5 | 42.5 | 45.5 | 48.5 | 52.5 | 56.5 |

| minimum | 8.94 | 11.57 | 13.4 | 15.7 | 19 | 22.6 | 25.4 | 17.3 | 30.9 | 33.1 | 37.9 | 40.9 | 43.9 | 46.9 | 50.6 | 54.3 | |

| mw | minimum | 7.15 | 9.26 | 10.7 | 12.6 | 15.2 | 18.1 | 20.32 | 21.8 | 24.72 | 26.48 | 30.32 | 32.72 | 35.12 | 37.52 | 40.48 | 43.68 |

| s | maximum | 16 | 18 | 21 | 24 | 30 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 |

| minimum | 15.73 | 17.73 | 20.67 | 23.67 | 29.16 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | |

| Thousands of pieces weight KG | 8.83 | 13.31 | 20.96 | 32.29 | 57.95 | 99.35 | 149.47 | 207.11 | 273.81 | 356.91 | 494.45 | 611.42 | 772.36 | 959.18 | 1158.32 | 1372.44 | |

FAQ

Q: What is Your Main Pro Ducts?

A: Our Main Products Are Fasteners: Bolts, Screws, Rods, Nuts, Washers, Anchors and Rivets.meantime, Our Company Also Produces Stamping Parts and Machined Parts.

Q: How to Ensure That Every Process's Quality

A: Every Process Will Be Checked by Our Quality Inspection Department Which Insures Every Product's Quality.

In The Production of Products, We Will Personally Go to the Factory To Check the Quality of Products.

Q: How Long is Your Delivery Time?

A: Our Delivery Time is Generally 30 to 45 Days. or According to the Quantity.

Q: What is Your Payment Method?

A: 30% Value of T/t in Advance and Other 70% Balance on B/l Copy.

For Small Order Less Than1000usd, Would Suggest You Pay 100% In Advance to Reduce the Bank Charges.

Q: Can You Provide a Sample?

A: Sure, Our Sample is Provided Free of Charge, but Not Including Courier Fees.

delivery

Payment and Shipping

surface treatment

Certificate

factory