✔️ Material:Stainless Steel(SS)304/Carbon steel/Aluminum

✔️ Surface:Plain/White Plated/Yellow Plated/Black Plated

✔️Head:Round

✔️Grade:8.8/4.8

Product introduce:

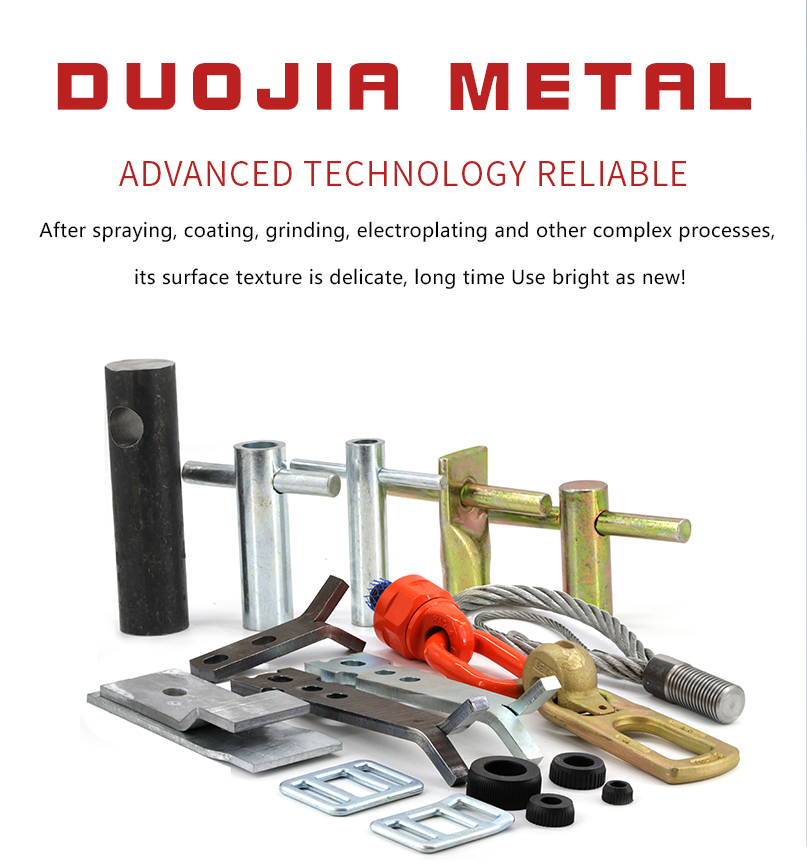

Lifting eye bolts are essential hardware for lifting and rigging operations. This particular lifting eye bolt is constructed from high – strength materials, likely alloy steel, which is often heat – treated to enhance its tensile strength and durability. The bright orange coating is typically a type of powder coating, providing excellent corrosion resistance and high visibility, which is crucial for safety in industrial settings.

The eye portion is designed to allow the attachment of slings, chains, or ropes, enabling the secure lifting of heavy loads. The threaded shank is meant to be screwed into a pre – tapped hole in the object to be lifted. It has clearly marked load – rating information, which indicates the maximum weight it can safely handle, ensuring users can select the appropriate bolt for their specific lifting tasks.

Usage Instructions

- Inspection: Before use, carefully inspect the lifting eye bolt for any signs of damage, such as cracks, deformations, or excessive wear on the eye or the threads. Check that the load – rating markings are legible and that the coating is intact.

- Selection: Select the correct size and load – rated lifting eye bolt based on the weight of the object to be lifted. Never exceed the specified working load limit.

- Installation: Ensure the hole in the object where the eye bolt will be installed is clean, free of debris, and has the correct thread size. Screw the eye bolt into the hole by hand until it is hand – tight, then use a suitable wrench to tighten it further. Do not overtighten, as this can damage the threads or the material of the object.

- Attachment: Attach the lifting slings, chains, or ropes to the eye of the bolt. Make sure the attachment is secure and that the load is evenly distributed.

- Operation: During the lifting operation, ensure that the load is balanced and that the lifting equipment is in good working order. Do not jerk or shock the load.

- Maintenance: Regularly clean and inspect the lifting eye bolt. Lubricate the threads occasionally to prevent corrosion and ensure smooth removal and reinstallation if needed. If any damage is detected, immediately remove the eye bolt from service and replace it.