✔️ Material:Stainless Steel(SS)304/Carbon steel/Aluminum

✔️ Surface:Plain/White Plated/Yellow Plated/Black Plated

✔️Head:Round

✔️Grade:8.8/4.8

Product introduce:

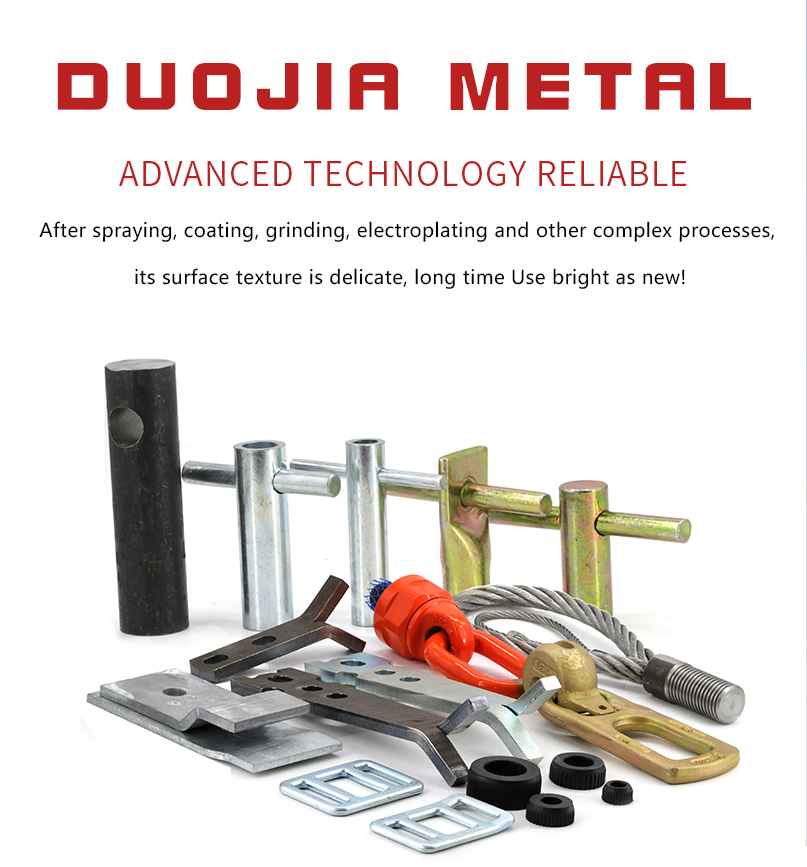

The lifting socket with cross bar is a specialized hardware component used in lifting and rigging applications. It is typically made from high – strength steel, which is often hot – dip galvanized or coated with other anti – corrosion finishes to ensure durability and resistance to environmental factors.

The socket part is designed to receive a lifting pin or bolt, providing a secure connection point. The cross bar adds stability and ease of handling, allowing for better control when attaching and detaching lifting equipment such as slings or chains. This design helps distribute the load evenly, enhancing the overall safety and efficiency of lifting operations. It is commonly used in construction, mining, and industrial manufacturing sectors where heavy objects need to be lifted and moved.

Usage Instructions

- Inspection: Before use, carefully inspect the lifting socket with cross bar for any signs of damage, such as cracks, bends, or excessive wear on the socket or cross bar. Ensure that the anti – corrosion coating is intact.

- Selection: Choose the appropriate size and load – rated lifting socket based on the weight of the object to be lifted. Refer to the manufacturer’s specifications for the working load limit.

- Installation: Insert the lifting pin or bolt into the socket, ensuring a proper fit. Make sure the cross bar is oriented correctly for easy handling and load distribution.

- Attachment: Connect the lifting slings, chains, or other equipment to the cross bar or the socket in accordance with the recommended attachment methods. Ensure that all connections are secure and tight.

- Operation: During the lifting process, monitor the socket and its connections for any signs of stress or movement. Do not exceed the rated load capacity.

- Maintenance: Regularly clean the lifting socket with cross bar to remove dirt, debris, and any corrosive substances. Check for signs of wear or damage during routine inspections and replace the component if necessary. Store it in a dry, protected area to prevent rust and corrosion.