On November 13th, the statement made by Parmeras' forward, Rock, at the press conference of the Brazilian national team sparked a lot of discussion - this promising young player, who has scored 20 goals and provided 5 assists in the past six months, admitted that he regained his competitive form under the trust of the head coach Abel Ferreira. Meanwhile, the state of São Paulo where Parmeras is located is quietly experiencing a wave of sports venue upgrades. The key component that drives this infrastructure boom - the Brazilian sleeve (Hex Bolt Sleeve Anchor WZP).

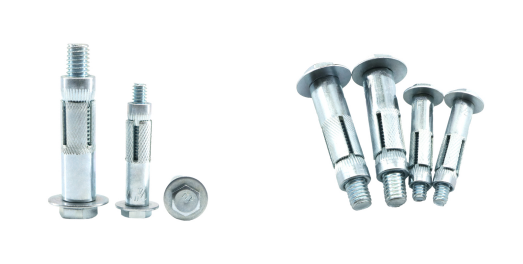

"Hex Bolt Sleeve Anchor WZP" is not just a regional product name; it is a general term used internationally for a specific type of high-strength post-expansion threaded anchor. It got its name due to its wide application in large-scale engineering projects in Brazil and other places, representing the mature technology and high reliability standards of this type of product.

Hebei Duoga Metal Products Co., Ltd., as a professional international foreign trade company in hardware, has keenly grasped this market demand. The technical director of the company, Mr. Zhang, said in an interview: "Our WZP series Brazilian sleeves have a core technology based on the 'mechanical locking' principle. It does not rely on chemical bonding but forms a huge and secure wedge-shaped locking force in the concrete substrate through the interaction between a precise conical bolt and the expansion sleeve. This purely mechanical connection method ensures that even in dynamic loads or vibration environments, it can provide a durable and stable anchoring effect."

The main uses and functions of Hex Bolt Sleeve Anchor WZP make it an indispensable connection component in modern construction projects. Its core value is reflected in the following three aspects:

1. Excellent load-bearing capacity: This product is specifically designed for installing heavy equipment in undamaged concrete. Its unique sleeve design expands uniformly when the bolt is tightened, greatly increasing the contact area with the concrete, thus providing extremely high shear and tensile bearing capacity.

2. Convenient installation: Compared to chemical anchors that require waiting for curing, the installation process of Brazilian sleeves is faster. Just drilling, cleaning the hole, inserting the anchor bolt, and tightening it with a wrench, which significantly shortens the construction period and reduces labor costs, especially suitable for projects with strict efficiency requirements.

3. Wide application scenarios: The application scenarios of WZP Brazilian sleeves are extremely wide, covering multiple key fields:

Structural engineering: used for connecting steel structure beams and columns, fixing large bridge components, and reinforcing tunnel linings.

Equipment installation: used in factories, power stations, and water conservancy facilities to fix heavy machinery, transformers, pipeline systems, and pump sets.

Public facilities: widely used for fixing highway guardrails, traffic signs, stadium seats, and large advertising boards.

Building curtain walls: used to securely anchor stone, glass or metal curtain walls to the main structure.

Currently, South American countries such as Brazil and Chile are vigorously promoting energy transformation and infrastructure modernization, involving a large number of wind power, photovoltaic power stations and ultra-high voltage transmission projects. These projects have extremely strict requirements for the fatigue resistance and corrosion resistance of fasteners.

Hebei Duoga Metal Products Co., Ltd. precisely entered this market hotspot. Its WZP Brazilian sleeve products can provide different grades of carbon steel or stainless steel materials according to customer needs and adopt advanced surface treatment processes such as hot-dip galvanizing (HDG) to cope with the corrosive environment of high humidity and high salt in the Brazilian coastal areas, ensuring an extremely long service life of the product under harsh conditions. We are not merely selling products; we are offering a complete set of anchoring solutions. Our team will provide precise selection suggestions and technical support based on the specific application scenarios, substrate conditions, and load requirements of the customers. This customer-centric service model is the key to winning the trust of the Brazilian market for us.

Post time: Nov-14-2025